Delivering Mavis Downs: Another Complete Conveyor Solution Underway

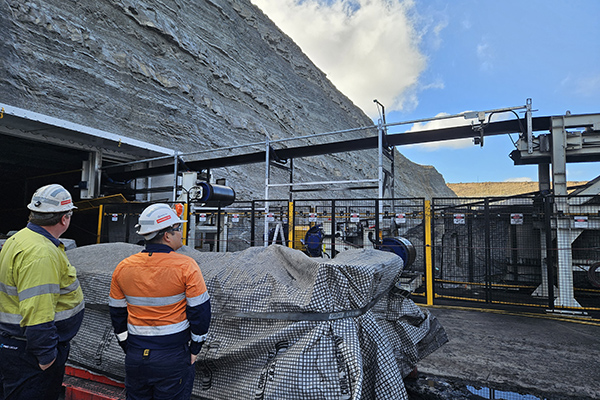

Fenner Conveyors engineering division, Australian Conveyor Engineering (ACE), has made significant progress on the delivery of a comprehensive conveyor solution to PIMS Group’s Mavis Downs mine.

Mavis Downs Mine is located between Moranbah and Coppabella at the existing Millennium Mine complex, approximately 170km West of Fenner Conveyors’ Paget facility. The mine has been designed to produce 1.2MTPA of high quality PCI and coking coal for the export market, utilising ‘Bord and Pillar’ mining methods.

The project brief involves the design, supply and commissioning a 1050mm wide conveyor system capable of handling 800 TPH of ROM Coal.

ACE were successfully awarded the $5.9 million contract in March 2022 by PIMS Mining Pty Ltd to supply three Caddy conveyors, three Caddy Junior conveyors and one Radial Stacker.

Senior Mechanical Engineer, Juan Cacdac, said, “We have gained invaluable experience working with a new client on - bord and pillar operation in the Bowen Basin. We have delivered a number of Longwall Maingate and Trunk systems in the past, so it has been refreshing to have a different set of challenges to design equipment for.”

With the project spanning over 21 months to-date, ACE was able to identify ways to support PIMS Group with added-value opportunities, such as the supply of additional infrastructure to suit site conditions.

Due to geological variations, ACE also worked closely with the client to provide ongoing engineering support during installation.

Project Manager, Tim Gray said, “We had the opportunity to adapt our standard conveyor systems to a unique environment allowing us to showcase the versatility of the equipment whilst providing opportunities to add value by providing site-specific engineered solutions.

The project is a perfect example of the intercompany collaboration within the Fenner Conveyors Group. ACE’s Mackay team managed the conveyor design and supply. Fenner Conveyors manufactured the solid woven PVC Conveyor Belt out of its factory in Revesby, New South Wales, and supplied splicing and mechanical crews to support belt installation. Part of the Conveyor Roller supply were delivered from the ACE Idler Plant in Brisbane, Queensland. Fenner Conveyors’ service teams completed the commissioning of the conveyor system and are carrying out ongoing support and maintenance of the mechanical systems now the equipment is in operation.

“Engaging the Fenner Conveyors Group provides the best outcomes for our clients because we are able to cohesively manage the project from concept through to commissioning.” explained Gray.

“As a Group we bring more experience and better project efficiency.”

To date the three Caddy Juniors, Radial Stacker, and two of the three Caddy systems have been delivered. Supply of the final conveyor is planned for December this year, with PIMS Group’s installation schedule continuing into 2024. ACE’s site service team will provide support during conveyor installation and commissioning.