Purple Conveyor ready to roll for Kestrel Coal Resources

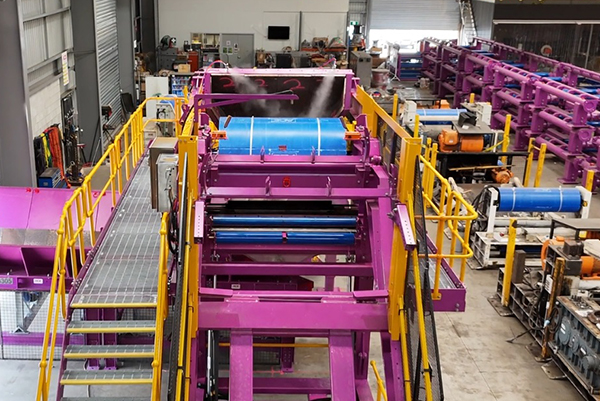

Fenner Conveyors is proud to announce that the latest community conveyor, painted purple in support of the local Emerald community, is ready for dispatch to site as part of the Kestrel Coal Resources ‘500s Project’.

The project, involving the design, manufacture, installation and commissioning of four maingate conveyors and four substations for the mine located in the Bowen Basin region, is a partnership between Kestrel Coal Resources and Fenner Conveyors.

Each conveyor system is delivered by Fenner Conveyors’ subsidiary Australian Conveyor Engineering (ACE). ACE specialise in the engineered conveyor systems, providing vital capabilities to the comprehensive Fenner Conveyors offering in Australia.

The third maingate conveyor, which is the same design as the first two except for a few innovative design changes, was mocked-up by the ACE team in November 2023 before being stripped down and sent to site for installation.

One of the design changes is a safety improvement to the belt clamps, which was suggested as part of collaborative discussions with Kestrel to address the previous belt clamp design specified for site not having any specific safety factors. Another change is the focus on dust suppression, a significant challenge commonly faced by coal mines.

One of several innovations on this conveyor system, is the development of an improved belt clamp design, which, through development with Kestrel, resolved safety issues identified on their other conveyor systems utilised onsite. This system now, provides both positive locking and clamping redundancy in the event of loss of power or component failure.

Another focus for development and improvement, was dust suppression and ventilation control.

Workshop Manager, Joel Hingst, said that the team performed a live trial of the dust suppression units in the Mackay workshop.

“The units we selected use water atomising nozzles to reduce water consumption and improve dust suppression. Other units on the market use a lot of water, however the design for this conveyor uses a compressed air and water suppression system to produce finer water droplets, in conjunction with engineered placement of nozzles and ventilation control devices – all to support the core goal of reducing the generation of dust, spillage and improving dust capture,” Hingst said.

The project has grown since initial concepts with both Mackay and Somersby teams. As part of the initial contract, Kestrel outlined the requirement for three substations. However, after further discussions, an extra substation was put forward which ACE was successfully awarded.

Now, well and truly into the project, ACE is on track to deliver four substations and one overhaul out of its Somersby facility in NSW. The purple conveyor is scheduled to be completely assembled and installed on site by March 2024.

The third community group selected to be represented by the purple conveyor is Emerald Neighbourhood Centre, a local organisation that provides information, referral and support, as well as crisis counselling and emergency relief to the Central Highlands community.

Branch Manager of ACE QLD, Scott Manley, said that the 500s Project has also been a great opportunity for career development and collaboration within the team.

“During mock ups of the equipment in the Mackay workshop, we get engagement from engineering, workshop and site services team members to review and improve our products. This promotes collaboration between the various departments and personnel improving overall outcomes.”

“Such a large-scale project allows us to refine and develop the operational requirements of the equipment. This results in a better outcome for the customer, as we have the opportunity to develop the system to suit their operation,” Manley explained.

ACE are the leading contractor for the project. “It’s our preferred project format for contracts and what we’re looking to do more of; partnerships with our clients are the goal. As part of the Fenner Conveyors group with diverse and expansive capabilities for engineered conveyor solutions, we are best-placed in the industry to deliver this for our clients.”

The fourth and final conveyor will be painted orange for Men’s Shed Emerald, a community-based organisation that offers a safe and friendly environment for men to work on meaningful projects. Production of the orange conveyor has already begun from the Mackay workshop.

A large part of the fourth conveyor will be completed in Quarter 2, 2024, with the whole project assembly and delivery to site due to be wrapped up by Quarter 3, 2024, and a commissioning period following.

Fenner Conveyors and ACE are committed to supporting the local communities where they operate and are proud to be a partner in Kestrel Coal Resources’ 500s Project.