MOVING TOWARDS SUSTAINABLE CONVEYING

MOVING TOWARDS SUSTAINABLE CONVEYING

Fenner Conveyors is committed to "A Better Way Forward" for all generations. In accepting our responsibility as a member of our communities, we seek to demonstrate our commitment to protecting the environment by minimising the environmental impact of all our operations.

Explore actions around our "All-Sustainable" approach below.

CIRCULAR BELTING SOLUTIONS

Giving End-of-Life Conveyor Belts a New Life!

At Fenner Conveyors, sustainability is at the heart of everything we do. Our partnership with Tyrecycle delivers a circular, Australian-made solution for end-of-life conveyor belts, helping reduce landfill and lower emissions for mining operations.

Through this collaboration, used belts are collected from mining sites, processed at Tyrecycle’s facilities in Western Australia, and reintroduced into new downstream products. Clients can visit both Fenner Conveyors and Tyrecycle’s facilities to see the recycling process in action, ensuring transparency and trust.

This initiative is a key part of our commitment to driving innovation and long-term sustainability for our clients and the broader industry.

We are proud to make sustainable choices every day.

We are proud to make sustainable choices every day.

At Fenner Conveyors, we understand that sustainable actions help make a real difference for the future of our planet. Here are just some of the sustainability initiatives we are proud of.

Since we have the conveyor belt manufacturing process down to a science, we can run manufacturing equipment at our factories meaningfully to reduce gas, and conserve energy and electricity at our plants.

We proudly use as much renewable or recycled material in our rubber covers as we can.

Our employees volunteer at tree planting initiatives annually and participate in climate workshops to improve environmental awareness.

Our low-rolling resistant conveyor belt bottom covers and conveyor rollers are industry-leading, and help our customers achieve significant energy savings. Our R&D for LRR products is a focus so we can enhance our offering further.

We produce conveyor products that are used to move recyclable materials

We represent our brand with merchandise, employee uniforms and print materials which are 80% or more sustainable.

Our X Series conveyor belting products are designed to outperform

comparable plied offerings, using less materials in production and weighing less in operation.

We’ve installed solar at our manufacturing and service locations across Australia to lower our reliance on grid-generated electricity, as well as give back own renewable energy to the grid.

We don’t focus on purchasing offsets (carbon credits). Instead, we dedicate resources to sustainability initiatives that have impact.

All Fenner Dunlop Conveyor Belting is produced

domestically which means less carbon emissions are produced during transportation to a customer site.

We’ve installed electric car charging stations at several locations to support our employees to make sustainable transport decisions.

More with less

CONVEYOR BELTING WITH GREAT SUSTAINABILITY BENEFITS.

More with less

CONVEYOR BELTING WITH GREAT SUSTAINABILITY BENEFITS.

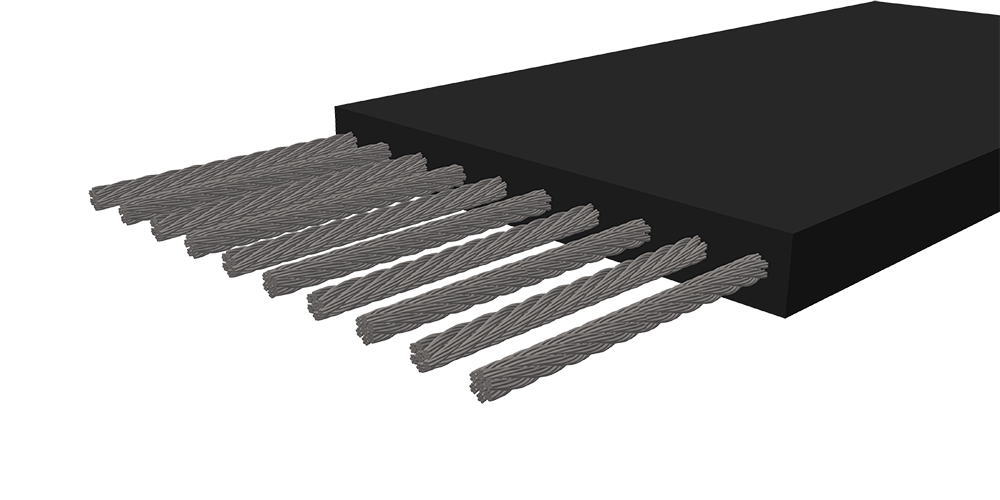

Historically, conveyor belts have been manufactured using two or more plies of fabric that are adhered to each other using inner layers of rubber. When additional rip, tear and impact resistance was required for a more demanding bulk material handling application, the obvious answer seemed to be fitting a belt with even more plies with even thicker covers. Which was proved to be very rarely the best solution.

The best solution is to fit belts that are specifically engineered for the purpose, which is the philosophy of Fenner Conveyors. We research, develop, trial and test all conveyor belting products to ensure the longest lasting and most durable solutions. This in turn provides sustainable outcomes at a site level with extended belt life and less waste from changed-out equipment.

Our X Series is comprised of unique, single unit (dual unit in some circumstances) carcasses weaved and treated at our state-of-the-art manufacturing facilities. Here we have total control of the weaving process, which ensures the integrity and quality of the belt vs. the common practice of purchasing standard belt weaves in the textile commodity marketplace – which are predominantly manufactured overseas.

Fenner Conveyors is proud to manufacture the longest lasting conveyor belts in the world. This means our customers benefit from requiring fewer replacements belts, which creates less unnecessary waste.

Our X Series conveyor belting products remove the need for multiple plies and rubber skims, which saves valuable resources and creates a more robust product.

We optimise the consumption of nylon and polyester in our carcass constructions to manufacture the best product possible product with the least amount of physical materials needed.

GREEN SERIES

CONVEYOR PRODUCTS DESIGNED TO IMPROVE ENERGY EFFICIENCY OF YOUR SITE.

GREEN SERIES

CONVEYOR PRODUCTS DESIGNED TO IMPROVE ENERGY EFFICIENCY OF YOUR SITE.

Low rolling resistance means that less force is required for a belt to roll over idlers. This efficient cover compound is applied to the bottom cover of conveyor belt to support a reduction in indentation loss and improvement in shear modulus, resulting in an overall reduction in power consumption.

We offer light-weight, low noise rollers, resulting in less friction and less energy consumption from seized or misaligned rollers. Our roller solutions are high-quality, Australian-Made designs, reducing change-outs and overall site waste.

Related stories

-

Fenner and Tyrecycle are Transforming Mining's Toughest Waste

When belts reach the end of their service life, the question of what to do with them has, until now, been met with few viable answers. -

Fenner Conveyors and Tyrecycle Partnership Aiming to Reshape Sustainability

As a part of the ResourceCo Group, Fenner Conveyors and Tyrecycle are leveraging their global networks to unlock cutting-edge circular solutions in Australia. -

Fenner Conveyors and Tyrecycle Forge a Strategic Partnership to Power Circular Innovation in Mining

A strategic collaboration bringing together complementary rubber expertise and a shared desire to support mining customers with circular mining solutions. -

Proud Sponsor of the ICBMH 2026

Fenner Conveyors is proud to be the Technical Sponsor for Day 1 of the upcoming International Conference of Bulk Materials Storage, Handling & Transportation -

Lighting Up Plants & Workshops Across Australia

Fenner Conveyors successfully installed solar energy systems across our manufacturing plants and service workshops throughout 2024. -

A Paragon in Energy-Efficient Conveying

Discover how Fenner's PowerSaver and Yeloroll-HD boost conveyor efficiency and cut carbon for sustainable mining. -

Fenner Conveyors : Facilitating a Full-Service Solution

Fenner Conveyors delivers end-to-end conveyor solutions for mining, combining tech, engineering, service, and sustainability. -

Fenner Conveyors Enhances In-House Rubber Extrusion Capabilities

Fenner Conveyors boosts in-house rubber extrusion for splice kits, cutting lead times and supporting local Australian supply.

Want to know more?

More information is available on Planet initatives for the Michelin's Group of Companies.