Fenner Conveyors : Facilitating a Full-Service Solution

Published in APAC Outlook Mining

Merging expertise, efficiency, technology and sustainability, Fenner Conveyors stands above the competition as the market-leading provider of mining conveyor systems. We speak to executive members of the company to find out more.

FACILITATING A FULL SERVICE SOLUTION

Mining is a key industry that keeps our modern world moving. Unearthing the planet’s myriad of minerals and ores is key to the production of cars, the construction of buildings, and the continuation of life as we know it.

Australia is home to a monumental mining sector. Within it, there operate companies that facilitate mining activities to help businesses achieve the best results in the field. Fenner Conveyors (Fenner), a Michelin Group Company, is a notable player in the sector, and the leading manufacturer of conveyor systems for mining and industrial applications, a critical aspect of heavy-duty operations bringing to the market engineered conveyor products, surrounding services and support to the Australian mining space.

“The mining industry is very exciting in terms of delivering minerals to fuel the growth of sectors as a fundamental resource,” introduces Tony Pace, CCO of Engineering at Fenner.

The mining space is exciting for Australia as a country that provides a significant proportion of the world’s iron, coal, gold, and emerging minerals such as lithium (crucial for the development of batteries), and is therefore an equally integral part of the overall global economy.

According to Pace, the importance of these minerals cannot be understated. For example, a substantial percentage of Australian coal is used for manufacturing steel, which in turn is a key material for producing electric vehicles (EVs) and wind turbines globally.

Traditionally, Fenner is synonymous with conveyor belts, but this is changing. Following its multiple acquisitions over the years, Fenner has succeeded in establishing itself as a complete offering for anything in the industry, from conveyor field services to the design, manufacturing and monitoring of conveyor systems, the latter of which is carried out through digital technologies supported by its maintenance and field service teams.

Fenner’s breadth of capability far exceeds its traditional conveyor belting products. The company has engineered conveyor components and systems, established methodologies for conveyor installations and change-out equipment, and uses the information it gains from conveyor monitoring to develop new products and compounds that are engineered for belting. Fenner utilises its many brands to bring its clients the best conveyor solutions, a delivery unique to the company.

BUYING AND BUILDING

As it stands today, every part of a conveyor can be engineered, manufactured, and installed by Fenner. In order to do so, engineering capabilities are absolutely critical. Fenner has been growing its engineering capabilities over the years through its in-house conveyor belt engineers. Furthermore, part of Fenner’s service offering includes engineered methodologies for belt installation and change outs, delivered through Victoria-based company, Belle Banne Conveyors, acquired in 2010.

The acquisition of Australian Conveyor Engineering (ACE) in 2012 was a key part of this new direction of the business. ACE provides Fenner with the ability to design conveyor systems, pulleys, and everything else that is part of the process, including all electrical system components such as the starters and drive motors.

Last year, Fenner made the acquisition of Conveyor Products & Solutions Pty Ltd (CPS) which operates as the company’s primary roller manufacturer based in Western Australia. This development was the last piece of the puzzle to form where Fenner currently stands in 2023. Today, a customer can request that Fenner designs and engineers a system, a modification, or supplies conveyor products, as well as maintains such systems, which is all part of the company’s key strategy.

“The engineering element is critical to this; we are the only original equipment manufacturer (OEM) in the industry that can actually deliver a complete conveyor. It is a real point of differentiation for us in the conveyor field,” notes Trevor Svenson, Executive General Manager.

“We also want to help our customers to reduce their operating costs. We have the expertise in belting, maintenance, modelling material and many other aspects to influence the operation of assets, meaning that we can make customers’ systems more efficient while providing all kinds of products and components that make them more durable as well.

“Nobody else in the industry globally can offer what we can; if clients wish to get these results elsewhere, they will have to work with multiple companies, whereas Fenner is the one place you can actually do and have it all,” he adds.

SOURCING LOCAL

One of Fenner’s strengths in the market is that of being a local supplier to Australian mining players. According to Pace, the past decade in the country has seen a real shift away from sourcing products and services from cheaper, international suppliers to securing a localised supply chain and supporting local businesses in the process.

Reduced price often compromises longevity. Instead of focusing on bottom-line pricing, mining companies are recognising the value of high-quality and full-service partners who can offer above and beyond the simple hardware, and reliably provide products, services and support to systems to further secure the continued success of mining operations.

Fenner picked up on this shifting sector focus, and has since made the strategic decision to invest in its local operations in Perth, Australia, standing out with a unique market offer to be a reliable and superior quality provider of belts, components and much more. This is a true differentiator for Fenner and one that gives the company an edge over its competition in the market.

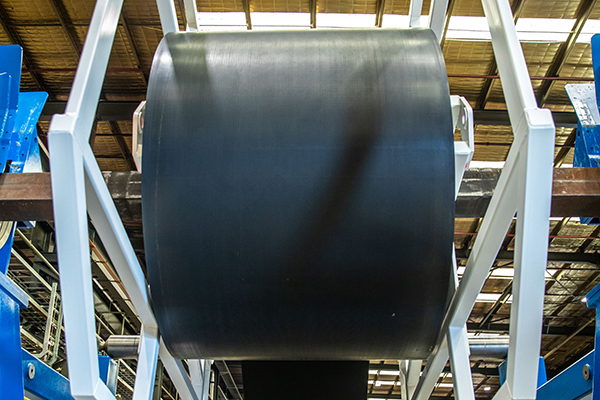

“10 years ago, we built a factory in Perth during a time when many people were looking overseas for production, and it was a major investment in the area,” Pace explains. “We added two production lines over the course of a few years, with a third production line having been commissioned late last year, so now we can manufacture very high-quality conveyor belts and all the parts locally in Australia for local customers.”

This convenience, quality and reliability is further bolstered by Fenner’s exceptional coverage of all customer needs via its field services and support, an integral part of the company’s offer to the market.

“We are quite unique as we can design the conveyor system, manufacture the hardware, metalwork, and belt. Then, we can install the conveyor system and belt, and once it’s all up and running, we maintain the whole thing for the customer,” Pace continues. “We offer the full-service package in terms of total cost of ownership around a conveyor system.”

COM-MISSION SUCCESS

Fenner’s undertaking of Anglo American Plc’s (Anglo American) Aquila project is an example of the company’s ability to deliver such services. In 2020, Fenner was selected to design, supply and install a 2.6 kilometre (km) overland conveyor located in the Bowen Basin Coalfield, alongside four drives, a transformer, loop take-up, elevated gantry sections, overland structure, and belting. The conveyor is a crucial piece of infrastructure for the coal mine, not only as a means of extraction but also to ensure the streamlining of the entire operation.

“We have over 1,000 people in the business and almost 75 percent of our employees are typically in on-site operations doing service work on conveyors and maintaining engineering, and they do a fantastic job across our many projects in the field,” Svenson says.

“Overland conveyors are a large market for the company, and we have a lot going on in the Queensland coal industry. A couple of years ago, we secured a contract to build an overland conveyor for Anglo American, and we delivered that as a turnkey project.”

Fenner’s role on this operation consisted of designing, manufacturing, installing and commissioning the conveyor that the company continues to maintain to this day. For Svenson and the team, this was the first substantial project to bring together the collective capabilities incorporated from Fenner’s multiple acquisitions. This is where the industry expertise, tools and know-how from engineering functions, showcased Fenner’s ability to answer industry demands in a diverse mining space.

DELIVERING SUSTAINABLE SOLUTIONS

More recently, Fenner secured a five-year contract with a major iron ore-producing customer based in Western Australia, which itself is an area seeing a great deal of growth in the mining sector.

“There are both well-established and emerging iron ore producers tapping into our natural resources,” Svenson tells us. “For us at Fenner, this is an area that we are keen to support; our largest conveyor belt manufacturing plant – and the largest press-line in the world – is well-placed in the Western Australia region with 300km of belting coming out of the production facility each year.”

By nature of the industry, continuing iron ore operations sees mining activities take place ever further away from the initial processing plants. At this point, operators have two choices: they can either build another processing plant at the new pit, or they can convey the ore to the original processing plant. For many, the latter is the most cost-effective way to do it.

“The issue comes with distance, and consequently, energy usage,” Pace continues. “A conveyor that transports ore 20km to a processing plant requires a vast amount of power and so many mining companies are recognising this, shifting to a more environmentally conscious approach and reducing their carbon emissions.”

This is another advantage that Fenner has when it comes to its offering; an ability to supply customers with conveyor products which promote energy efficiency and lower overall carbon output. The company’s conveyor rollers include a range that is very efficient when it comes to reducing the amount of energy consumed during conveyor operations – known as CPS’s Yeloroll-HD. On top of this, Fenner can also provide conveyor belts with low rolling resistance through its PowerSaver compound, which means smoother and more energy-efficient flow over the idlers. Combine these two, and you have a sustainability-centric offer, making Fenner the market-leading choice when it comes to environmentally focused conveyor systems.

Having proven its capabilities in this area, Fenner believes that it is the company to deliver sustainable conveyor benefits to clients operating in the mining space in Australia, and will continue to develop its offering in this space.

AT THE CORE

Owned by Michelin Group, Fenner echoes the company’s three pillars of sustainable growth: people, to commit to the safety, development and inclusion of its employees; profit, to deliver financial value and innovation in its conveyor products, services and solutions; and planet, to make a positive impact on the environment and the globe by using recycled materials, lowering carbon emissions and more.

“Above everything, our team’s safety in the field is incredibly important to us,” Pace adds.

“By being part of Michelin Group, we also have access to a vast R&D department consisting of thousands of personnel working on product development as well as new and improved components and systems to deliver value to clients. On top of this, Michelin’s renowned rubber expertise in tyres is applied to Fenner’s conveyor belts, making them the superior option on the market, and helping develop safer products, methods, and systems for those who install, operate, and maintain them.”

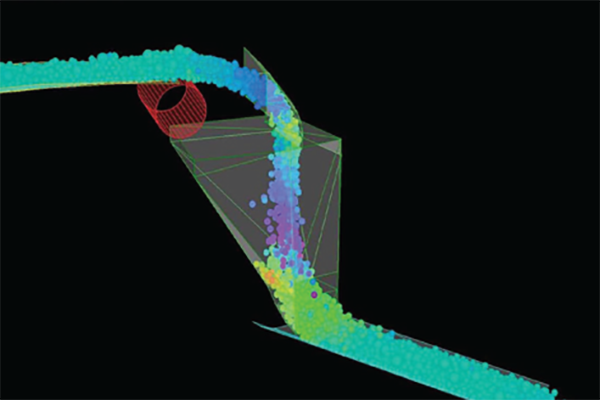

Fenner’s R&D encompasses critical technological developments that are key to the company’s systems service and support for its customers. Digitalisation and conveyor monitoring are a large part of this and are paramount to the streamlining and cost-effectiveness of conveyor systems.

“We have invested heavily in technology as an organisation over the past few years, including conveyor monitoring,” Svenson elaborates. “For example, there has been high customer demand for real-time monitoring to keep track of the rate of wear for a conveyor belt.

“Another prime example is the rate of roller wear; a conveyor system that is 24km long will make use of tens of thousands of rollers. Monitoring the performance and wear of these rollers is critical to the continued function and safety of the system, as well as – especially the case for worn rollers – saving costs by reducing belt damage.”

This technology focus ties into Fenner’s nature as an innovative company, collaborating with partners to maximise the advantages of monitoring systems while supplying belts that utilise Michelin Group’s advanced polymer technology for efficiency and durability. This focus on monitoring and increasing the service life of conveyor systems further adds to the company’s sustainability-centred mission.

THE CONTINUATION OF QUALITY

Fenner benchmarks its manufacturing emissions via an independent organisation, through which targets are set to be achieved in line with those of Michelin Group. Innovating with products when it comes to reducing environmental impact is a well-established aspect of the company.

“Fenner’s ability to deliver is a unique point of difference in the industry,” Svenson says. “On top of this, carbon emission reduction is a real focus for us. 10 years ago, we didn’t envisage that a combination of these acquisitions would put us in a really good position to contribute to utilising sustainable materials when making products, and on top of this, reduce overall carbon emissions.”

This sustainability-centric focus is exemplified by Fenner’s collaborative iron ore project with global mining giant Rio Tinto and subsidiary, CPS. This ongoing project will involve an overland conveyor for a new enterprise called Western Range. Fenner utilises its belt manufacturing capabilities merged with CPS’ rollers which are less resistant and more economical when it comes to energy usage, leading to less carbon emissions released into the atmosphere as a result.

“These rollers and beltings are partially made from sustainable materials, either natural rubber or recycled,” Svenson details. “As part of Michelin Group, there is a strong focus on these sustainability targets and metrics, looking towards 2030, 2050 and beyond. That’s where we stand out in the industry with our key mining clients, as they want to work with us to actually make an impact in that space.

“We intend to continue bettering the mining industry in Australia by offering a higher quality full design, installation and manufacturing services, supported and maintained by our expert teams while utilising the latest in digitalisation and monitoring tools for a more efficient and sustainable future of mining conveyors.”