Conveyor Products

Conveyor Rollers

Innovative, robust roller technologies to provide the best performance in any application.

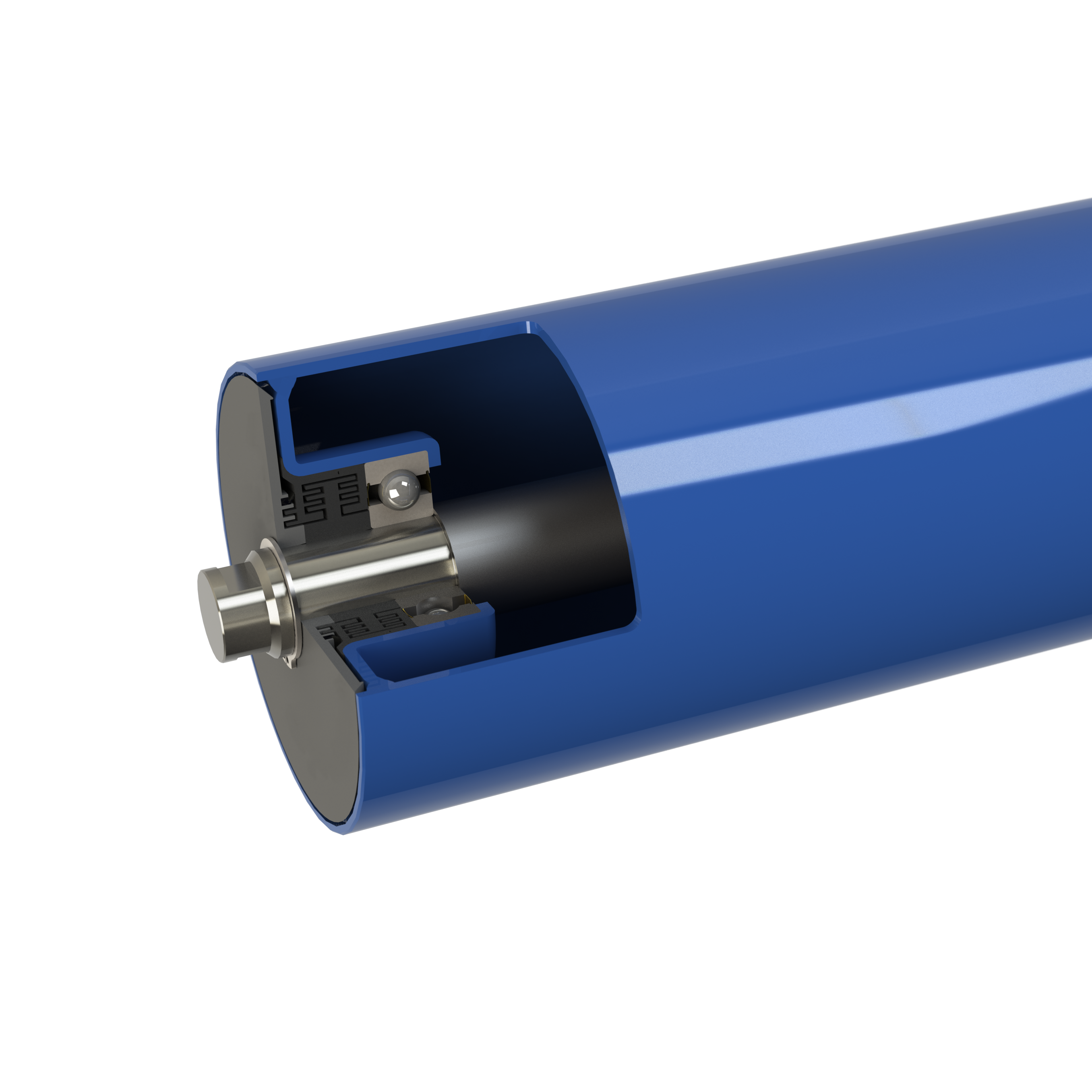

Steel Rollers

- Shell thickness above industry standards

- Use of high speed conveyor tube for consistent TIR

- High quality sealed-for-life bearings

- Economy range offers inner welding of pressed housings

- Premium range takes this one step furhter with a custom nylon press-to-fit housings, to further eliminate risk of belt cutting and damage

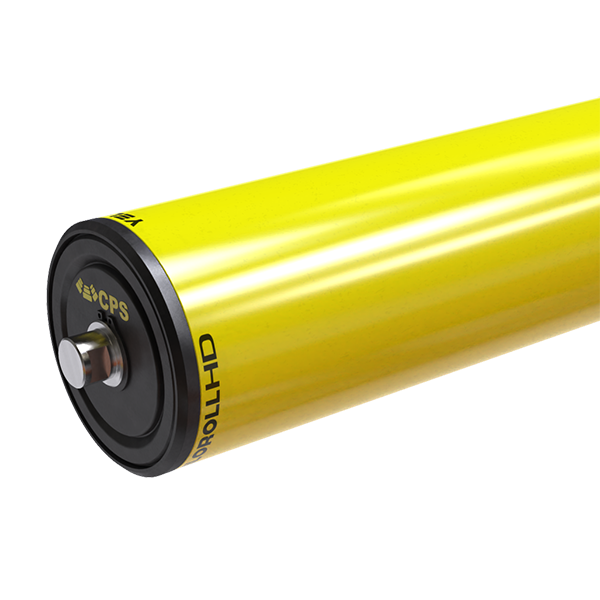

Composite

- Manufactured using a specifically formulated modified PVC shell

- Up to 45% lighter than equivalent steel rollers

- Provides occupational health and safety benefits and significantly reduced noise levels

- Highly corrosion-resistant

- Non-magnetic

- Impact-resistant

- Low breakaway mass and generating significantly less carry-back

Specialty Rollers

In addition to our composite and steel rollers, we offer a number of specialty rollers, custom designed for specific applications.

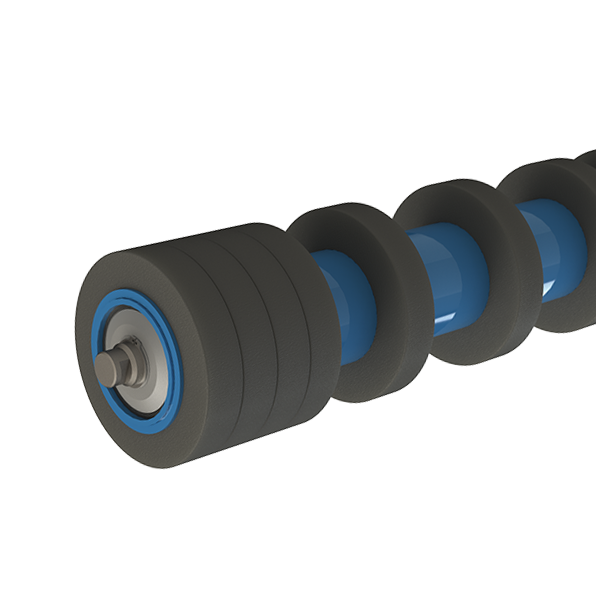

- Rubber disc return rollers (RDRT)

- Rubber impact rollers

- Rubber lagged steel rollers

- Suspended rollers

- Weigh rollers

- Rockshield seal option

- Servo guide rollers

Why choose our rollers?

It's our quality design, local manufacturing and rigorous QA systems that set us apart from other roller providers. We have a team of engineers and 1a national network of service branches which means help is never far away.

High quality doesn’t mean high cost

While the initial capital cost of a roller is often the only commercial consideration in a new product purchase, the total life-cycle cost is generally much more important. Each phase in a roller’s life has an associated cost, from the initial capital expenditure through to the running costs, downtime and cost of disposal and replacement.

Fenner Conveyors can work with site operations to synergise these processes and help reduce the total roller cost. We design specifically for site conditions so our rollers are not over or under-engineered, ensuring we maximise running efficiency and reduce power consumption – ultimately saving you even more money.

Resources

Related stories

-

Conveyors for a Cause: Final Community Conveyor Delivered to Kestrel Resources

Fenner Conveyors, in partnership with Kestrel Coal Resources, has successfully completed four maingate conveyor systems for the Emerald Mine. -

Understanding Belt Wear: Why Cover Grade Matters

In demanding operations conveyor belts are subjected to punishing forces. The survival of a belt in such conditions hinges on the resilience of its cover rubber -

ArmorShield in Lithium Processing

Since the installation of the new ArmorShield belts in January 2025, the site has reported zero incidents of belt rips, cuts, or visible wear on the top covers. -

Imitation vs Innovation: The Hidden Cost of Counterfeit Parts in Australian Mining

Counterfeit and imitation parts that fail under pressure are increasingly threatening industry performance and profitability, and the impact continues to grow. -

Fenner Conveyors and Tyrecycle Forge a Strategic Partnership to Power Circular Innovation in Mining

A strategic collaboration bringing together complementary rubber expertise and a shared desire to support mining customers with circular mining solutions. -

Belle Banne’s Latest Belt Puller: 25 Years of Evolution and Innovation

The Belt Puller by Belle Banne is an established piece of equipment that has become indispensable for efficient conveyor belt installs and changeouts. -

Wharf Belt Replacement: A First at Pilbara-Based Port Operation

Collaboration between Fenner Conveyors and a valued Pilbara client has ensured the successful completion of a major wharf conveyor belt replacement. -

Value Up Close and Personal

Fenner Conveyors is offering its customers the opportunity to visit its manufacturing facilities and see how its products are made.