Who we are

At Fenner Conveyors, employee health and safety is our prime objective. Safety will never be compromised on our sites or when working on yours.

Our Occupational Health and Safety (OH&S) Mission Statement states that Fenner Conveyors commits to providing a safe and healthy work environment for all employees, contractors and visitors. In doing so, we strive to reach our target of:

100% SAFE BEHAVIOUR AND CONDITIONS, TODAY

Fenner Conveyors Australian Safety Framework

The Australian Safety Framework provides the safety systems to foster & support safe work practices throughout the businesses - from onboarding to day-to-day activities and continual employee development.

SafetyCircle

In an effort to transform and drive safe behaviours to a new level, Fenner Conveyors has adopted a simplistic approach designed to breakdown the Australian cultural barriers of approaching our mates on keeping safe. Overcoming the challenges of having a safety conversation for all team members regardless of level.

The behavioural-based safety approach uses straight forward language and ideas to enable self-responsibility, self-leadership, situational awareness and active risk management at all levels.

High Risk Work

In addition to high-risk work licensing activities, conveyor installation is one of the most high-risk activities our workforce undertakes.

Fenner Conveyors' commitment to supporting employees and reducing exposure associated with high-risk work, is demonstrated through programs such as:

- Belt Pull Caluclation Training (providing accreditation to use the Fenner Belt Pull Calculation Tool©)

- Verification of Competency (VOC) Framework

- Belt Installation Training

Hear about the safety culture at Fenner Conveyors from our employees

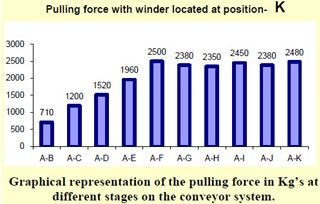

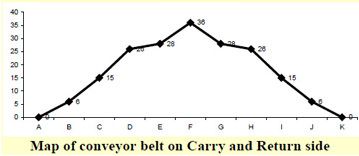

Fenner Conveyors Belt Pull Calculation Tool©

The Fenner Conveyors Belt Pull Calculation Tool© is used to accurately determine the forces required to pull the conveyor belt around the system prior to the job commencing. This is essential to ensure correct selection of equipment such as belt winders, winches, pulling cables and pulling plates. The importance of assessing the pull force goes far beyond carrying out a risk assessment and is essential to ensure the task is carried out safely and incident free.

This tool has been developed in conjunction with independent registered engineers and takes into account pulleys, idlers, gearboxes and using the many years of experience gained in the field by Fenner Conveyors personnel. Extensive testing has also been conducted in the field to verify the accuracy of the tool.

Related stories

-

Wharf Belt Replacement: A First at Pilbara-Based Port Operation

Collaboration between Fenner Conveyors and a valued Pilbara client has ensured the successful completion of a major wharf conveyor belt replacement. -

Workshops Launched: Fostering Respectful Behaviours in the Workplace

Fenner launches ‘Respectful Behaviours’ workshops to foster a safe, inclusive workplace and address psychosocial safety risks. -

First Year of K-Mix Construction Complete with 100% Safety Maintained

Fenner marks 1 year of K-Mix plant construction with zero injuries, boosting local jobs, safety, and sustainable manufacturing. -

Exceeding Quality Underground

ACE delivers custom, compliant underground mining equipment that exceeds Australian standards for safety, reliability, and performance. -

Pod Mods in Hunter Support Safety Milestone Achievement

Hunter team celebrates 365 days injury free, supported by safety workshops, pod mods, and a strong culture of risk awareness. -

1 Million Hours Recordable Injury-Free: A Remarkable Safety Milestone for the Belle Banne Conveyors Team

Belle Banne Conveyors celebrates 1 million injury-free hours, showcasing commitment to safety, teamwork, and workplace well-being. -

Innovative Conveyor Solutions for Enhanced Efficiency and Safety

ACE's in-house load testing ensures VSD substations perform reliably on-site by identifying issues before installation. -

Fenner Joins Push-Up Challenge for Mental Health

Fenner Conveyors joined the 2023 Push-Up Challenge, completing 126,000 push-ups and raising funds to support mental health awareness.

Can't see what you're looking for?

Contact your local Fenner branch to find out more about our full range of products and services.