Modulaveyors

A CONVENIENT AND COST EFFECTIVE SOLUTION FOR MATERIAL CONVEYING ACROSS A WIDE RANGE OF INDUSTRIAL APPLICATIONS.

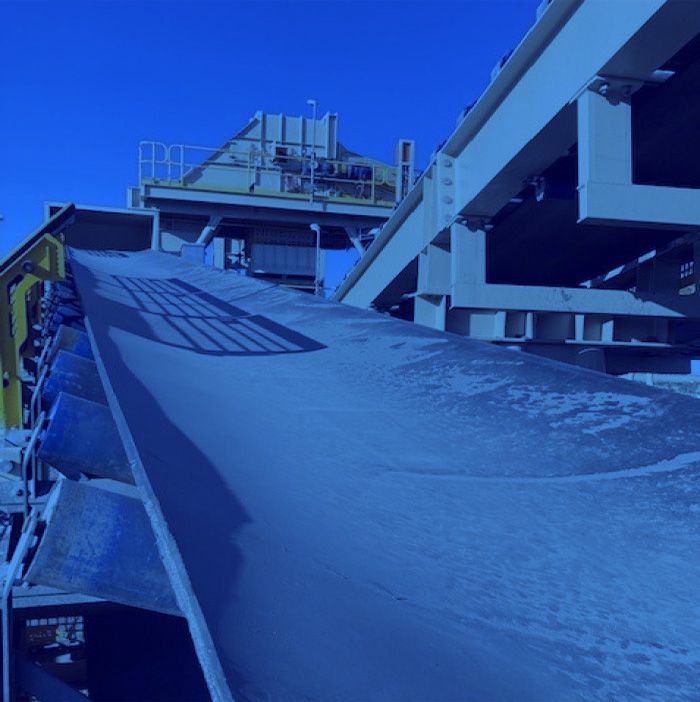

Modular conveyor systems

The unique modular design of Fenner Conveyors' Modulaveyor systems allows for effortless on-site delivery and reassembly, making them the perfect choice for conveyors that require frequent relocation.

With a significantly reduced manufacturing time compared to custom conveyors, the Modulaveyor provide a fast and efficient solution to meet your project needs, and can be commissioned and delivered far faster than typical conveyor systems.

Industry Applications

Fenner Conveyors’ modular conveyor systems have revolutionised material handling across Australian industries. The Modulaveyor system provides a versatile, efficient, and cost-effective solution, designed to adapt to a wide range of industrial applications while ensuring optimal performance and reliability.

Quarrying

Modular conveyors revolutionise quarry operations by optimising the movement of bulk materials. They open up efficient transport for raw materials such as stone, gravel, or sand through various processing stages. Additionally, they facilitate seamless loading and unloading onto trucks or other transportation modes, enhancing overall quarry productivity.

Construction

Seamlessly integrate the ModulaveyorTM into your construction operations to boost efficiency. Whether you’re loading concrete molds, assembling automotive components, or fabricating steel, this versatile system allows for easy adjustments to meet changing production demands.

Manufacturing

Whether handling raw materials, assembling components, or manufacturing products this system’s flexible design allows for smooth adjustments to meet evolving production needs, fitting to your location's layout and unique requirements.

Mining

Modular conveyor systems enhance the efficiency of managing bulk materials within challenging mining settings. They are utilised across various industries for transporting raw materials like coal, ores, or aggregates through diverse processing phases. Additionally, with rapid deployment as a core competency, they make loading for transport significantly more efficient.

Warehousing and Logistics

Modular conveyors can be used for various tasks in warehousing and logistics, including sorting, picking, packing, and loading or unloading goods. They can also be adapted to suit the unique layout of each warehouse, ensuring optimal space utilisation and material flow.

Agriculture

Whether transporting harvested crops, sorting produce, or managing feed and fertiliser, modular conveyor systems enhance efficiency throughout the farming process. From field to storage or processing, these adaptable solutions streamline agricultural workflows, rapidly repositioned for optimal efficiency.

Food Processing

In food processing, modular conveyors can be used to transport ingredients, such as fruits, vegetables, or grains, through various stages of processing, including washing, cutting, mixing, cooking, and packaging. The stainless steel, easy-to-clean design of Fenner modulaveyors ensures compliance with strict food safety regulations and minimises the risk of contamination.

Bio Waste

Modular conveyors are pivotal in managing bio waste efficiently. They are tailored specifically for bio waste handling, and ensure seamless transportation through various stages of processing and disposal. Crafted with durability in mind, they meet stringent hygiene standards. The modular design allows for easy cleaning, minimising contamination risks and enhancing overall operational safety and efficiency in bio waste management.

Explore Succesful Modulaveyor Projects

Melbourne North-East Link

This project plans to fix missing links in Melbourne’s freeway network. To create these transportation lines, 6.5km of tunnels are being constructed spanning regions beyond Melbourne CBD. The Fenner Conveyors team have supported this project with the delivery of a custom-designed conveyor system.

Tasmanian Minesite

When 200 tonnes of materials were trapped in a Tasmanian mine after the existing conveyor system collapsed, a solution needed to be found and fast. Luckily Fenner Conveyors were able to provide with a 30m long modulaveyor, deployed and assembled in only 48 hours.

Is a modulaveyor right for your project?

Our expert team are happy to help determine if a modulaveyor is suited to your application and what optional inclusions will enhance your operation.

Download the Modulaveyor Brochure

Check out all the technical information, optional inclusions and industry applications in our brochure.

Endless customisation for your application requirements

Custom Cover Compounds

Whether it's oil resistance for food manufacturing or impact resistance for hard rock mining, modulaveyors fitted with belting that features our propietary cover compounds enhance the performance, durability and safety of your operation.

Air Operated Systems

For environments where electricity poses risks - such as underground or hazardous goods areas - our air operated conveyor offers a safe, reliable solution. Powered by compressed air, it eliminates the need for electrical components to comply with safety regulations.

Electrical Control Box

Designed to provide reliable, customised control for conveyor systems, these control boxes incorporate a variety of advanced control technologies such as programmable logic controllers, supervisory control systems, relay switches, Modbus, Ethernet and more.

Enhance system performance with these optional extras

Belt Scrapers

Belt scrapers are designed to effectively remove material build-up from conveyor belts, ensuring smooth operation, reducing wear, and extending the lifespan of your conveyor system.

Side Skirts

Skirting systems form a reliable seal at the load point to prevent spillage and dust, without damaging the belt’s top cover.

Underspeed

Speed Monitoring Sensors are devices that detect shaft rotation, stoppage, and reversal, ensuring safety in industries using rotating machinery.

Conveyor Covers

Conveyor covers provide essential protection from environmental elements such as dust, rain and sunlight, helping to extend the belts lifespan, reduce maintenance and ensure consistent, reliable operation in any conditions.

Touch Swift Drift

Ensure the safe operation of your conveyor system with belt drift switches, designed to detect misalignment of the conveyor belt. It automatically triggers when belt drift occurs, safeguarding both equipment and materials.

Custom Impact Zones

Enhance the durability of your modular conveyors with custom impact zones featuring UHMWPE panels, an extremely tough plastic designed to absorb the impact of heavy or abrasive materials, reducing belt wear and extending conveyor life.

Belt Weighers

Optimise your material handling process with belt weigher’s, which accurately measure the flow rate and total weight of materials being transported.

Technical Specifications

- Capacity up to 200t/h

- Available in widths of 450mm, 600mm and 750mm

- Conveyor lengths of 3m to 30m

- Trough or flat belt profile

- Drive: standard externally driven or motorised pulley

- Belt speed and power selection to suit any application

- Belting: Plain or cleated, rubber or PVC

- Tail load section cover

- Belt take-up captive screw

- Safety guards

- Surface finish such as powder coat, galvanised or stainless steel

- Single phase or three phase operation

Benefits

- Easy transportation and storage

- Lightweight design minimises installation time

- Variable speed drives (VSD) improves efficiency

- Reduced risk of belt damage

- Fully customisable head and tail sections for varied loading options and belt cleaning solutions

- Designed for road transport and compliant with sea freight container dimensions

Contact us or your local Fenner Conveyors branch for more information.

Related stories

-

Conveyors for a Cause: Final Community Conveyor Delivered to Kestrel Resources

Fenner Conveyors, in partnership with Kestrel Coal Resources, has successfully completed four maingate conveyor systems for the Emerald Mine. -

Understanding Belt Wear: Why Cover Grade Matters

In demanding operations conveyor belts are subjected to punishing forces. The survival of a belt in such conditions hinges on the resilience of its cover rubber -

ArmorShield in Lithium Processing

Since the installation of the new ArmorShield belts in January 2025, the site has reported zero incidents of belt rips, cuts, or visible wear on the top covers. -

Imitation vs Innovation: The Hidden Cost of Counterfeit Parts in Australian Mining

Counterfeit and imitation parts that fail under pressure are increasingly threatening industry performance and profitability, and the impact continues to grow. -

Fenner Conveyors and Tyrecycle Forge a Strategic Partnership to Power Circular Innovation in Mining

A strategic collaboration bringing together complementary rubber expertise and a shared desire to support mining customers with circular mining solutions. -

Belle Banne’s Latest Belt Puller: 25 Years of Evolution and Innovation

The Belt Puller by Belle Banne is an established piece of equipment that has become indispensable for efficient conveyor belt installs and changeouts. -

Wharf Belt Replacement: A First at Pilbara-Based Port Operation

Collaboration between Fenner Conveyors and a valued Pilbara client has ensured the successful completion of a major wharf conveyor belt replacement. -

Value Up Close and Personal

Fenner Conveyors is offering its customers the opportunity to visit its manufacturing facilities and see how its products are made.