Conveyor Belting

UsFlex Conveyor Belt

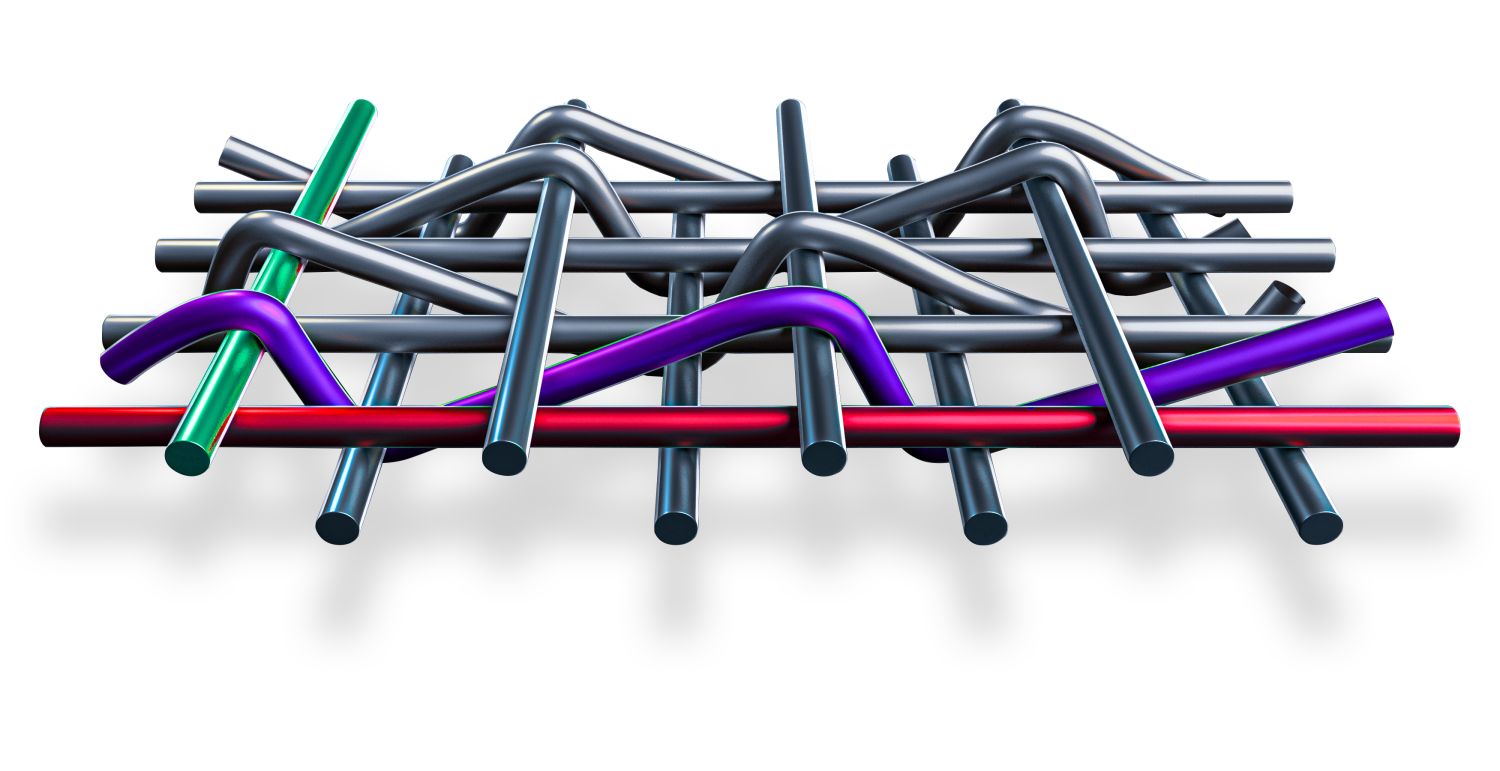

Unique straight warp construction Ply belt developed by Fenner Conveyors to deliver exceptional rip resistance and capacity to absorb extreme impact, with less stretch than traditional Ply belts.

Impact resistance up to three times greater

UsFlex belting has longitudinal rip resistance more than three times that of multiple-ply belts of equivalent rating due to our unique straight-warp construction. The straight laid yarns result in virtually no crimp. This results in a belt carcass with very low stretch compared to other fabric belts, making it suitable to replace steel cord belt in some situations.

Market Applications

Aggregates

Crushed Stone

Hard Rock

Heavy Metals

Sand & Gravel

Cement

Phasphate

Recycling

Why choose UsFlex?

UsFlex uses heavy-weight straight yarns in parallel planes – lengthwise and crosswise – locked together with a unique binder to concentrate belt strength. Our unique binder to weft combination is a built-in breaker to resist impacts and punctures.

The best carcass available for impact and tear situations

UsFlex is our straight warp weave fabric belt carcass, engineered to provide incredibly high impact resistance, as well as industry leading resistance to rip and tear. Flexibility is gained through yarn twist and this delivers outstanding troughing ability and permits the use of smaller pulley diameters.

The low stretch properties of UsFlex make it an alternative to Steel Cord belts in many applications, combining the strength of a Steel Cord belt with the toughness of a Ply belt.

UsFlex has resulted in significant reductions in downtime and improvements in belt life in mining applications, solving for cord failure through impact or high edge tensions, or where rip resistance beyond traditional Breaker Fabric is required.

Resources

Related stories

-

Conveyors for a Cause: Final Community Conveyor Delivered to Kestrel Resources

Fenner Conveyors, in partnership with Kestrel Coal Resources, has successfully completed four maingate conveyor systems for the Emerald Mine. -

Understanding Belt Wear: Why Cover Grade Matters

In demanding operations conveyor belts are subjected to punishing forces. The survival of a belt in such conditions hinges on the resilience of its cover rubber -

ArmorShield in Lithium Processing

Since the installation of the new ArmorShield belts in January 2025, the site has reported zero incidents of belt rips, cuts, or visible wear on the top covers. -

Imitation vs Innovation: The Hidden Cost of Counterfeit Parts in Australian Mining

Counterfeit and imitation parts that fail under pressure are increasingly threatening industry performance and profitability, and the impact continues to grow. -

Fenner Conveyors and Tyrecycle Forge a Strategic Partnership to Power Circular Innovation in Mining

A strategic collaboration bringing together complementary rubber expertise and a shared desire to support mining customers with circular mining solutions. -

Belle Banne’s Latest Belt Puller: 25 Years of Evolution and Innovation

The Belt Puller by Belle Banne is an established piece of equipment that has become indispensable for efficient conveyor belt installs and changeouts. -

Wharf Belt Replacement: A First at Pilbara-Based Port Operation

Collaboration between Fenner Conveyors and a valued Pilbara client has ensured the successful completion of a major wharf conveyor belt replacement. -

Value Up Close and Personal

Fenner Conveyors is offering its customers the opportunity to visit its manufacturing facilities and see how its products are made.