Hundreds of Inspections Completed using DigitalHub Mobile App

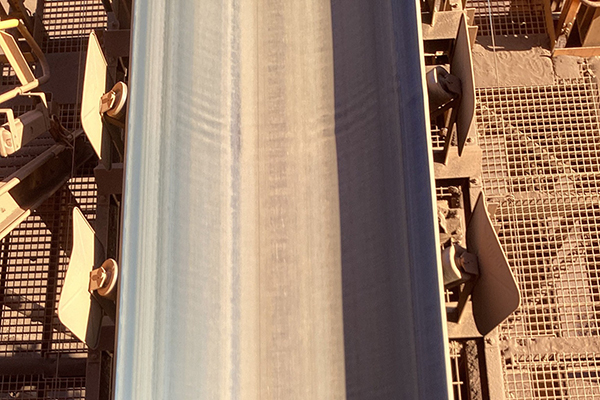

Digital inspections using Fenner’s DigitalHub mobile app are taking off at mine sites across Australia.

Following the launch of the DigitalHub mobile app in 2021, the technology team at Fenner Conveyors have seen a positive uptake in the mining industry.

Today, DigitalHub is being used by customers across different mining sectors, helping them to digitalise their preventative maintenance processes and gain insight into conveyors performance.

Conveyor Technology Manager, Samuel Wiffen, said while it’s a big change for mining companies the technology has been well received.

“Conveyors are systems of interconnected components. The impact of one component in poor condition can have a snowball effect on others. For example, poor skirt design or maintenance can lead to abnormal grooves in the belt, which can inhibit belt cleaners from performing optimally, leading to carryback,” said Wiffen.

“Issues like this not only reduce the belt life but also increase clean-up costs and, in some cases, increase roller replacement along the return.

“Using DigitalHub we can visualise these trends from inspections, belt thickness testing and idler data, all in one location.”

At current, the biggest issues trending on DigitalHub are abnormal wear and damage of belts, as well as poor hygiene and spillage.

“With one site using DigitalHub, we saw excessive carry-back issues. The fugitive material was increasing the frequency of clean up, leading to annual clean-up costs of over $20,000 per conveyor,” Wiffen explained.

Based on observations made during digital inspections and the data captured in DigitalHub by Fenner technicians, closer investigation was undertaken to the performance of the cleaning systems at the head pulley and this interaction with the belt.

“This allowed us to identify an optimal solution; upgrade the existing cleaner setup. We estimated that by doing this, carry-back along the return of this conveyor could be reduced by up to 75%.”

By undertaking this system improvement, the customer’s calculated return of investment was ten months.

“We understand the importance of demonstrating how this technology can revolutionise traditional mine sites. It’s a big step away from paper-based processes, and an even bigger step towards our overall vision for digitalisation across the business,” said Wiffen.

“We are so grateful for the support from the business, particularly the technicians, coordinators, and supervisors who are embracing DigitalHub in their daily activities on-site.”

“The most important thing now is for our team to continue getting out there using DigitalHub in their daily activities. The more data we can collect, the more we can value add to our customers with specialised solutions.”