Article published in Australian Mining

ACE has developed an underground dewatering system that increases residence time and water removal capabilities.

Respirable dust is a constant underground obstacle, particularly in coal mining operations where dust particles are often so...

Published in Safe To Work

Safety is at the forefront of everything Fenner does. Following a big safety win at the prospect awards earlier this year, the company has put its focus on managing fatigue within its employee network.

Fenner Conveyors can manufacture and supply...

Published in Industry Queensland

The Fenner Conveyors and Australian Conveyor Engineering (ACE) businesses in Mackay have started moving into a new 21,500sq m facility at 217 Farrellys Rd, Paget.

Part of the Michelin Group of Companies, Fenner & ACE commissioned the purpose-built...

Published in the Australian Bulk Handling Review

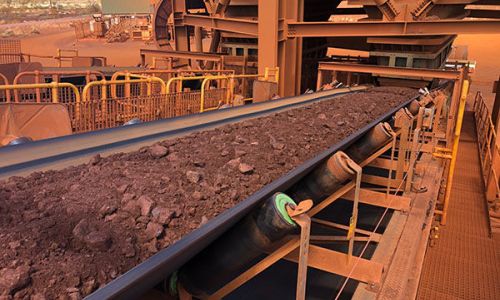

Fenner’s new UsFlex super-heavy-duty belt can withstand some of the toughest environments the iron ore industry can throw at it.

When it comes to conveying, iron ore is notoriously rough on belts. Fines – the small sand-like...

With the increasing awareness of the risks associated with respirable dust in underground coal mines, mining companies have been progressively introducing more and more water into the underground environment in an effort to manage the risk.

Due to nature of the mining process,...

ACE QLD records Safety Milestone of 12 months recordable injury free.

Last week the ACE QLD Team reached 12 months recordable injury free.

As part of the Fenner group of companies, ACE operates under the SafetyCircle program, instilling safe behaviours from the...

Article published in the Australian Bulk Handling Review

Fenner Dunlop Australia has announced its co-branding with Michelin, and will now be known as Fenner Conveyors, A Michelin Group Company.

The transition has been in development since Michelin acquired Fenner Dunlop in 2018.

While...