Conveyor Belt

THE BEST COMBINATION OF CARCASS & COVER COMPOUNDS TO MEET THE MOST DEMANDING APPLICATIONS

Conveyor belts have to withstand an enormous range of physical and environmental conditions as well as increasingly tough safety demands. To meet these demands conveyor belts need to have a carcass construction that is capable of handling extreme strains and forces. At the same time, the rubber covers must have resistance and durability required to protect that carcass over a long period of time.

It is the combination of carcass construction and rubber cover compounds that ultimately determine the operational lifetime of a conveyor belt and its overall cost-effectiveness.

You need both the cover compound and the carcass to work together to create the optimal product for your specific needs.

You need conveyor belts that provide the highest productivity for your operation.

You need Fenner Conveyors

conveyor belting on your system.

Conveyor Belt Manufactured in Australia

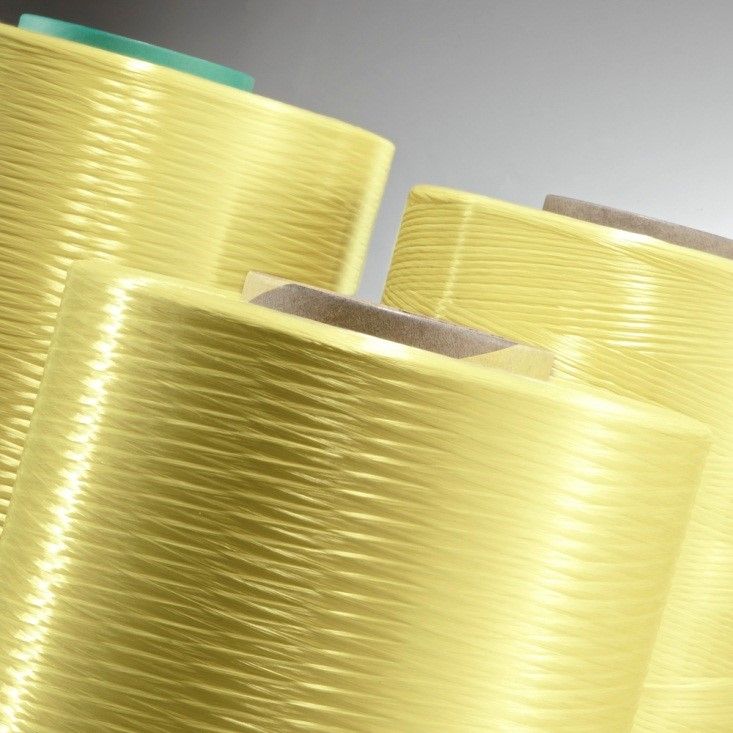

We're proud of our local manufacturing capabilities, offering an extensive range of Fabric Ply, Steel Cord, Aramid, and Solid Woven rubber conveyor belting - made right here in Australia at one of our state-of-the-art conveyor belt factories.

Over 150 years of conveyor belt experience

Fenner Conveyors is the local Australian manufacturer you need to keep your operations moving. We are passionate about making conveying safe, reliable and cost effective. All our belts undergo rigorous in-house and in-field testing to ensure we supply precisely the right belt for your application.

Industry-Leading Cover Compounds

Fenner Conveyors offer a conveyor belt covers for every application. Combine our quality conveyor belt carcasses and industry-leading cover compounds for maximum protection and performance.

Stock Belt Range

If you need belt in a hurry, we have a range of stock belt readily available from our national network of service centres - manufactured to exacting specifications and backed by our comprehensive warranty and support.

Specialty Belting

From cleated solutions for the most steeply inclined belts through to our endless slinger belts, we supply Australia’s largest range of specialty conveyor belts.

Related stories

-

Conveyors for a Cause: Final Community Conveyor Delivered to Kestrel Resources

Fenner Conveyors, in partnership with Kestrel Coal Resources, has successfully completed four maingate conveyor systems for the Emerald Mine. -

Understanding Belt Wear: Why Cover Grade Matters

In demanding operations conveyor belts are subjected to punishing forces. The survival of a belt in such conditions hinges on the resilience of its cover rubber -

ArmorShield in Lithium Processing

Since the installation of the new ArmorShield belts in January 2025, the site has reported zero incidents of belt rips, cuts, or visible wear on the top covers. -

Imitation vs Innovation: The Hidden Cost of Counterfeit Parts in Australian Mining

Counterfeit and imitation parts that fail under pressure are increasingly threatening industry performance and profitability, and the impact continues to grow. -

Fenner Conveyors and Tyrecycle Forge a Strategic Partnership to Power Circular Innovation in Mining

A strategic collaboration bringing together complementary rubber expertise and a shared desire to support mining customers with circular mining solutions. -

Belle Banne’s Latest Belt Puller: 25 Years of Evolution and Innovation

The Belt Puller by Belle Banne is an established piece of equipment that has become indispensable for efficient conveyor belt installs and changeouts. -

Wharf Belt Replacement: A First at Pilbara-Based Port Operation

Collaboration between Fenner Conveyors and a valued Pilbara client has ensured the successful completion of a major wharf conveyor belt replacement. -

Value Up Close and Personal

Fenner Conveyors is offering its customers the opportunity to visit its manufacturing facilities and see how its products are made.